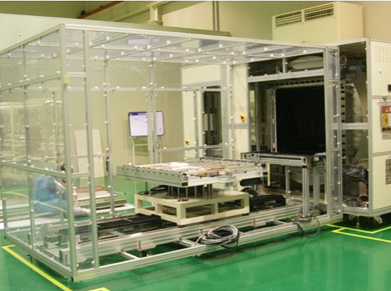

IN-LINE AUTOCLAVE

Summary

This equipment removes air bubbles by applying temperature and pressure to panel with polarized film during TFT-LCD manufacturing process.

Characteristic

The panel loaded in the loader section is simultaneously injected into the pressure vessel and the autoclave process is performed. When the process is completed, the panel is simultaneously discharged to the unloader, and then transferred one by one to the next process.

Specification

- Temperature range : 40℃~60℃

- Pressure range : 0~6Kg/㎠

- Temperature Control Accuracy : ±0.1℃

- Pressure control accuracy : ± 0.1Kg/㎠

- Uniformity :50℃ ±3 ℃

- power : 3 phase 208V 50/60Hz

MANUAL AUTOCLAVE

Summary

This equipment removes air bubbles by applying temperature and pressure to panel with polarized film during TFT-LCD manufacturing process.

Characteristic

Panel mounted on the cassette or tray can be put into the autoclave in batch and can be processed at once. It can be installed in the cassette logistics line for automation application.

Specification

- Temperature range : 40℃~60℃

- Pressure range : 0~6Kg/㎠

- Temperature Control Accuracy : ±0.1℃

- Pressure control accuracy : ± 0.1Kg/㎠

- Uniformity : 50℃ ±3 ℃

- power : 3 phase 208V 50/60Hz